This step by step diy woodworking project is about how to build a saltbox shed roof. If you have already built the frame of the saltbox shed, we recommend you to continue the job by building the roof. If you aren’t sure about the shape of the roof, you should take a look at the rest of the shed projects, as you might find a gable or a barn shape more appealing or easy to build.

There are may aspects that you should take into account before continuing the construction of the woodworking project. First of all, we recommend you to go to the town hall to check if a building permit is required. If this is the case, you need to read the instructions with attention and to make sure the location and the plans are in accordance with the legal requirements.

Building a saltbox roof is a complex project, as it has certain particularities that cannot be found in other cases. First of all, we recommend you to decide the slopes of the roof as to drain the water properly and to enhance the look of your garden. Work with attention and plan every step of the construction from the very beginning. Ask a skilled friend to assist you during the construction, as you need someone to hold the components locket together, while you insert the galvanized screws. See all my Premium Plans in the Shop.

Made from this plan

Building a saltbox shed

Materials

- D – 2 pieces of 2×4 lumber – 24″ long, 1 piece – 128″ long TOP RIDGE

- E – 8 pieces of 2×4 lumber – 34 3/4″ long, 8 pieces – 80″ long RAFTERS

- E – 10 pieces of 5/8″ plywood – 48″x96″ long SIDING

- F – 4 pieces of 3/4″ plywood – 48″ x 96″ long UNDERLAYMENT

- G – 2 pieces of 1×4 lumber – 128″ long TRIMS

- G – 120 sq ft of asphalt shingles SHINGLES

- 1 piece of 2×4 lumber – 12 ft

- 13 pieces of 2×4 lumber – 8 ft

- 2 pieces of 1×4 lumber – 12 ft

- 10 pieces of 5/8″ plywood – 48″x96″

- 4 pieces of 3/4″ plywood – 48″ x 96″

- 120 sq ft of asphalt shingles

- 2 1/2″ screws, 1 5/8″ screws

- 4d nails

- stain, glue, putty

Tools

- Safety gloves, glasses

- Miter saw, jigsaw

- Chalk line, tape measure, spirit level, carpentry pencil

- Drill machinery and drill bits

Tips

- Use a good miter saw to make the angle cuts

- Drill pilot holes before inserting the screws

Time

- One Week

Related

- Part 1: How to build a saltbox shed

- Part 2: How to build a saltbox shed roof

- Part 3: Build a shed door

How to build a saltbox shed roof

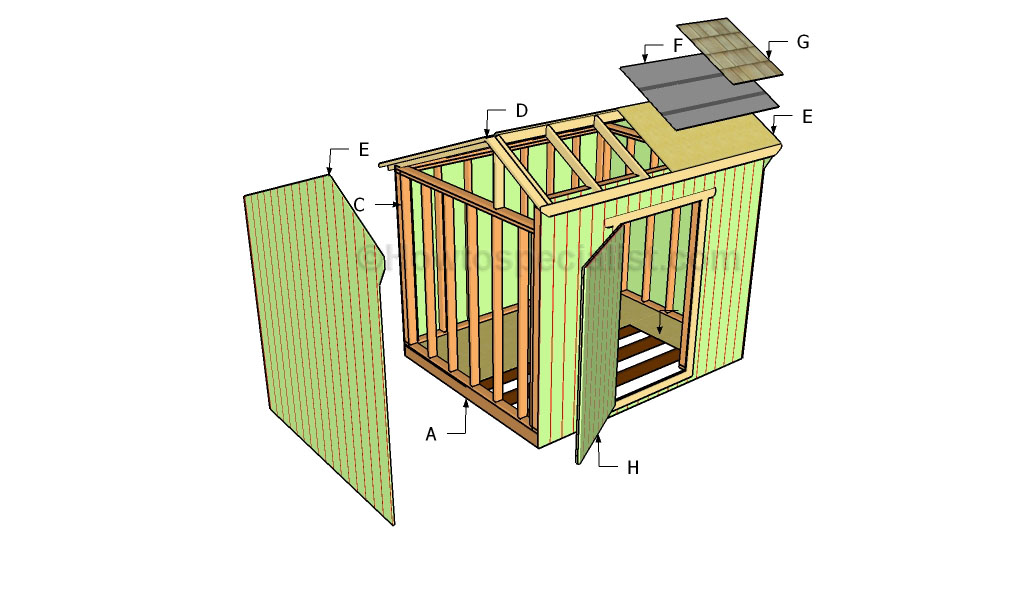

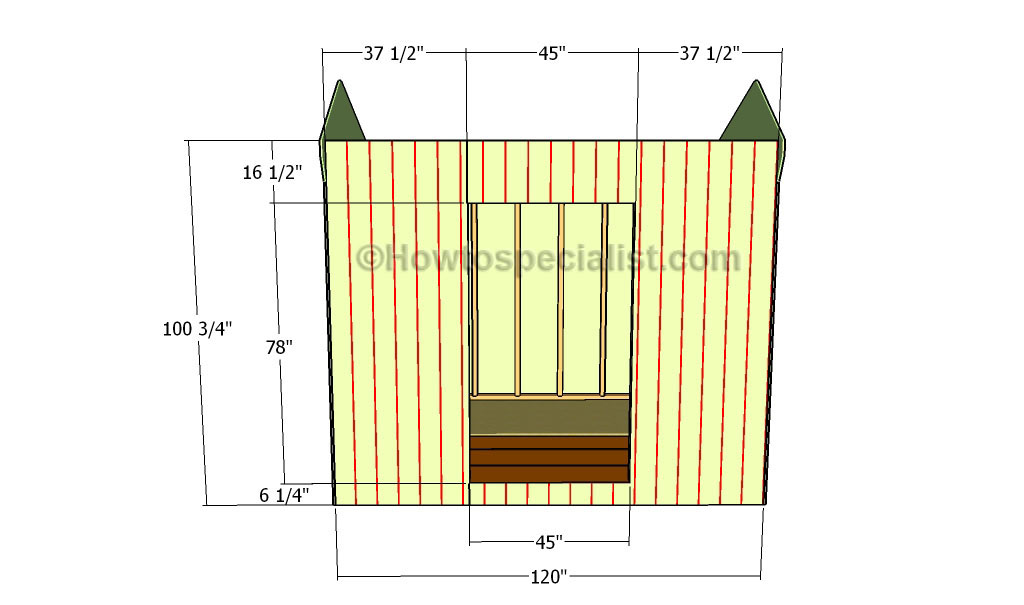

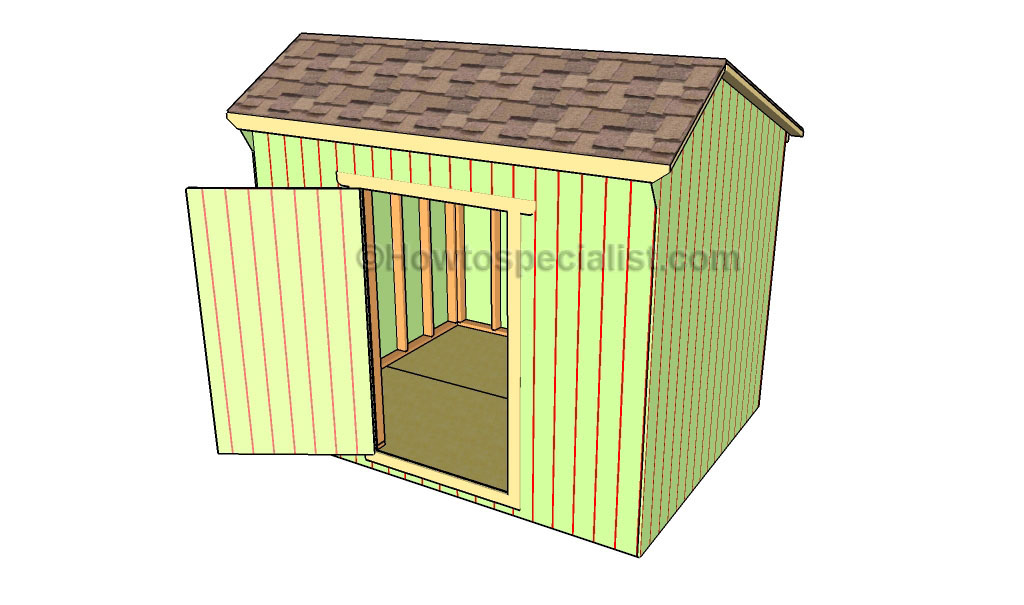

The first step of the woodworking project is to attach the 5/8″ siding to the exterior of the frame. As you can easily notice in the plans, we recommend you to align the sheets to the top of the framing and to lock them into place with finishing nails. Make sure the sheets are aligned properly at both ends. Mark the cut lines before adjusting the size of the sheets to right dimensions. Use a circular saw to get the job done in a professional manner.

Continue the project by attaching the sheets to the front of the saltbox shed. Make sure you cut the sheets properly, as to fit around the door opening. Drive several finishing nails through the siding to lock the sheets properly to the studs.

Use the same woodworking techniques described above to lock the siding to the back of the shed. It is essential to leave no gaps between the sheets, otherwise the saltbox shed won’t have a neat appearance.

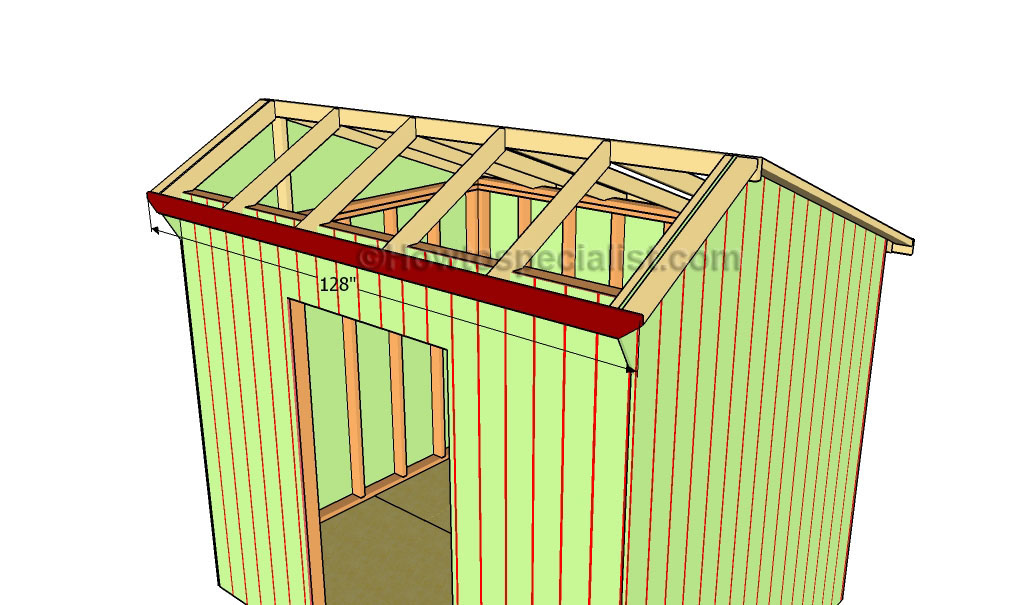

The next step of the project is to attach the top ridge to the walls of the shed, as described in the image. Drill pilot holes through the components before inserting the screws, to prevent the wood from splitting. Plumb the supports with a spirit level in order to make sure the structure is build properly. Place a spirit level on top of the top ridge to check if it is horizontal. Make the necessary adjustments if required. Leave 69″ and 22″ on both sides of the supports, as compared to the ends of the top rails.

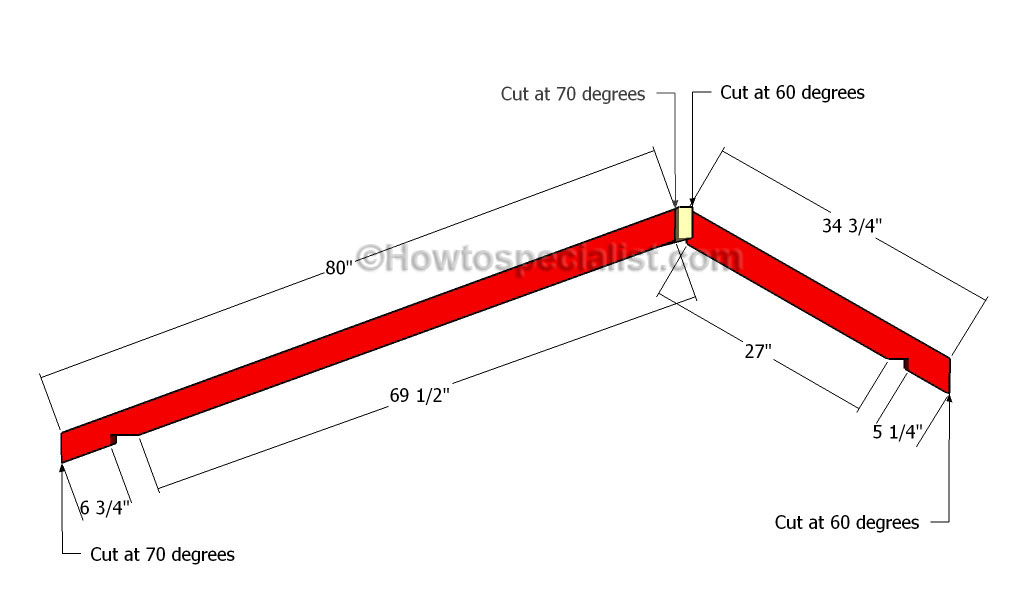

Building the rafters for the saltbox shed is a complex job, but if you pay attention to the instructions anyone can pull it through. Use a good miter saw to the make the angled cuts. It is essential to smooth the cut edges, otherwise the rafters might not fit into place easily.

Fit the rafters into place, making sure you keep them equally-spaced. Drill pilot holes through the rafters before inserting the 3 1/2″ galvanized screws into the top ridge and into the top plates. Pay attention to the ends of the rafters, as they need to be at the same level, otherwise the surface won’t be plane.

Attach 1×4 trims to the ends of the rafters, in order to get the job done in a professional manner and to enhance the look of the shed. Align the trims and secure them to the rafters by inserting several finishing nails.

One of the last steps of the project is to attach the 3/4″ plywood sheets to the rafters. Cut the pieces of 3/4″ plywood at the right size and lock them to the rafters with screws, every 6-8″. Make sure you don’t leave gaps between the sheets, in order to seal the roof properly and to prevent water damage.

Cover the plywood sheets with roofing felt, making sure the strips overlap at least 2″. Secure the tar paper to the plywood sheets with roofing staples. In addition, cut a 12″ piece for the top ridge. Fit the side drip edges over the roofing felt, while the bottom drip edges should be fit under. Place a starting course at the bottom of the roof, before installing the asphalt shingles. Always read the manufacturing instructions before starting the installation, as there are several aspects that differ.

Smart tip: The first course should start with a 3 tab shingle, the second course with a 2 1/2 tab , the third course with a 2 tab, the forth course with a 1 1/2 tab, the fifth course with a 1 tab, the sixth course with a 1/2 tab. Repeat the process from the beginning, starting with the seventh course. Don’t forget that the shingles should overhang from the drip edge about a 1/4″. In addition, secure the asphalt shingles to the roof decking with tacks. Fit the bottom drip edge under the roofing felt, while the side one should be over the tar paper.

Last but not least, we recommend you to take care of the finishing touches. Fill the holes with wood filler and let it to dry out for several hours. Use several braces to lock the walls together, otherwise they might move from position.

Smart tip: Apply several coats of stain or paint to the wooden components, if you want to protect them from decay and to enhance the look of the shed. Check out the rest of the project to see how to build the frame of the shed, as well as the door.

Thank you for reading our project about how to build a saltbox shed roof and we recommend you to check out the rest of the projects. Don’t forget to share our projects with your friends and LIKE us, by using the social media widgets, if you want to be the first that gets our latest articles.