This article is about how to make a wooden bed frame. Building a wooden bed frame is not a tough project, but an opportunity for both improving your skills and save some money. On the other hand, you might have not found yet a bed frame to fit your needs and tastes, so a diy project could be the solution to your problems. In this project we show you how to build a cheap and simple bed frame, made out of wood boards. The project requires one skilled person and several tools and materials (you can find in the below table). It is essential to decide the size of the mattress you are going to use, from the very beginning, and to draw a complete plan before starting the project.

Make sure you use proper materials for the wooden bed frame. Therefore, use high quality wooden boards and check them attentively before building the bed frame. The wooden boards must be perfectly straight and without any cracks or dents on their surface. Pine boards are good enough for the project, if you choose them wisely.

It is essential to build the wooden bed frame as rigid as possible. Therefore, we recommend you to use an L-square, to check if the corners of the frame are right-angled. If you install corner legs, it would be easier to fasten them to the frame, by locking them temporarily into position with a few C-clamps. In addition, if you want to hide the head of the screws, you could secure the boards from the inside of the frame, by using corner brackets or pocket holes. See all my Premium Plans in the Shop.

Made from this plan

Materials

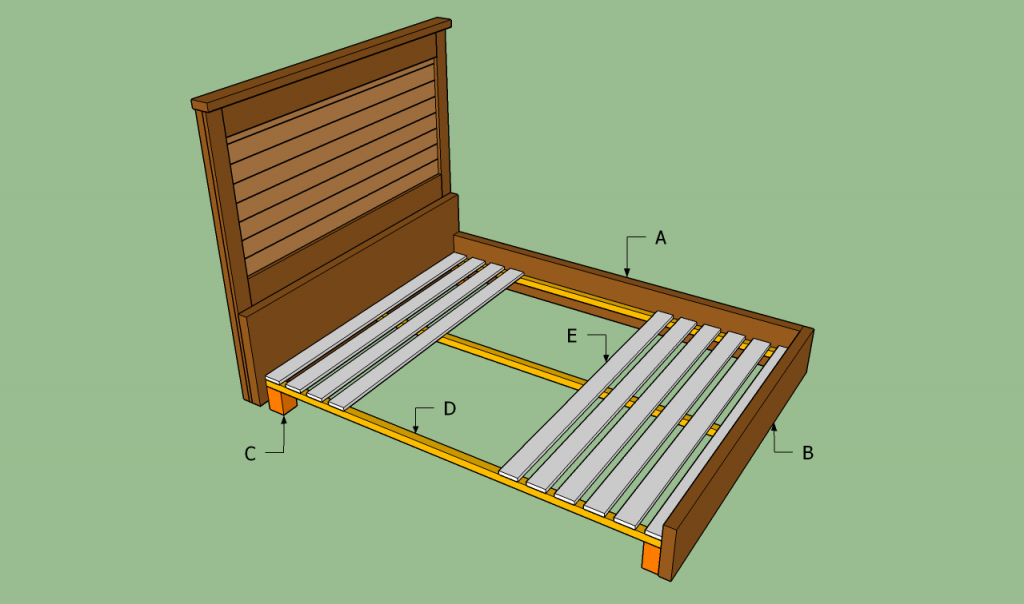

- A – 2 pieces of 2×10 lumber – 80 1/2” long SIDE COMPONENTS

- B – 2 piece of 2×10 lumber – 63 1/2” long FONT AND BACK FACES

- C – 4 pieces of 4×4 lumber – 5” long LEGS

- D – 3 pieces of 2×2 lumber – 80 1/2” long CLEATS

- E – 16 pieces of 1×4 lumber – 60 1/4” long SLATS

Tools

- Level, tape measure, carpentry pencil, l-square

- Rubber hammer, hammer

- Jig saw/circular saw, C-clamps

- Drill machine and drill bits

- Electric screw driver with torque control

Tips

- Read safety and disclaimer pages

- Select with great care the wood boards, otherwise the bed wouldn’t look properly

- When securing the bed joints use clams as to lock the wood boards

- Use a good drill machine with torque control to make pilot holes

Related

- How to build a storage bed frame

- How to build a queen size bed frame

- How to build a king size bed frame

- How to build a platform bed frame

Building a bed frame out of wood

When securing the bed frame corners, you have to drill the holes at least 1/3” from the edges of the wooden boards, as to prevent cracks or other damages. In addition, you can countersink the holes, as to hide the heads of the screws and to obtain a neat look. On the other hand, you could drive in screws and cover their heads with plastic covers, if you want to obtain a better aspect.

Preparation before building the bed frame

Drills, wood screws

In order to build the wooden bed frame, we have used wood screws and several drill bits for wood. It is important to use only bits made for wood, otherwise you can damage the boards or the drill machinery. Make sure the bits match the size of the screws.

In this article you will learn how to build a wooden bed frame, so read attentively our project and do not overlook any step, if you want to obtain a proper result. Make a thorough plan before starting the project.

Wooden boards

In this picture you can see the wooden boards we have used to build the bed frame. Use quality edge-glued panels due to the good cost-benefit ratio. These panels are very resistant and beautifully finished, so you won’t have to use sanding paper or an orbital sander to get a proper finish. In addition, we used two pieces of 2×2 lumber, in order to build the side railings, which will support the slats.

The slats should be made of 1×4 or 1×6 lumber, in order to support the weight of the matress. In our case, we have reused some old slats, but remember that we have selected only the best ones, we have polished them and painted with protective solutions. If you use unfinished boards, then you should use first an electric planer, and then for extra quality appearance a sander.

Tape measurement, framing square

In order to obtain proper, clean and straight cuts, we have used a framing square, a measuring tape and a carpentry pencil. Double check all the measurements.

Use a framing square to draw the cut lines

Mark the cut line with the pencil, in order to obtain a beautiful straight line. Use a framing square and check again if the corners are right- angled. Take accurate measurement, before marking the cut lines.

This technique is essential for your project, so work with judgment if you want to align the wooden boards perfectly.

Cutting the wooden boards

Setup for cutting wood boards

We used a few tricks to get perfectly straight cuts. You need a jig saw with a sharp and fine blade for wood, two C-clamps and another wood board with a straight edge. Firstly, place the second wood board, making sure the blade of the jigsaw goes exactly over the cut line, at both ends. Secondly, lock the wooden boards using the C-clamps.

Lock the hole setup into position either with the help of someone else or by using clamps and two sawhorses. This aspect is vital, otherwise you risk injuring yourself or damaging the components.

Marking the pilot holes

Use a measurement tape, framing square and a pencil to mark the places where you will drill the holes. First of all, the holes must be equally spaced. Secondly, the distance from the edge of the board to the marks should be half of the thickness of the wooden boards.

Building the bed frame

Drilling trough the boards

Choose a drill bit for wood with a size compatible with the screws. In this way. the wood screw would lock together the two wood boards. If you drill the hole using a smaller drill bit, then the two boards cannot be clamped properly.

Use a good drilling machine with torque control. At first, use low speeds to make sure the drill won’t slip from position. Afterwards, you can increase the speed. The wood board should be placed on top of a wood post, as to protect the drill bit and the support surface.

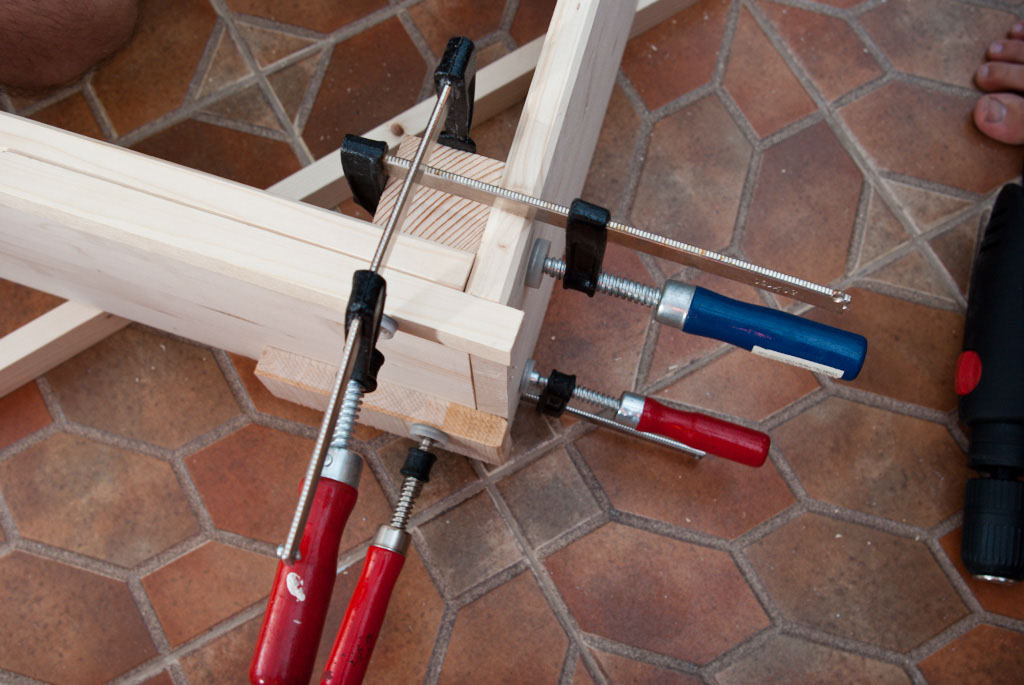

Setup for bed frame joint

You can see in the image the setup we use when making a corner joint of the bed frame. We have used four clamps and a square wooden post. This setup is essential for the job, as it secures firmly the boards which have to be screwed together.

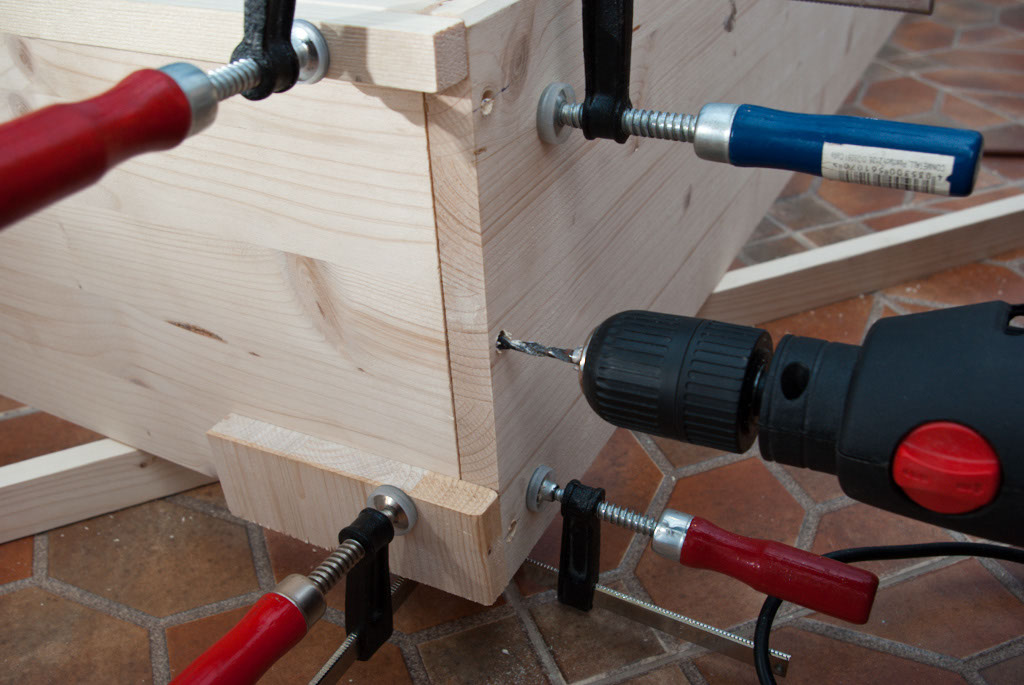

Drilling the bed frame to install the wood screws

Next, we have used the drill machine with torque control in order to make a hole in the adjacent wooden board. Note that this time we used a drill bit with a smaller size (read the instructions on the package of the wood connecting screws, for the exact size).

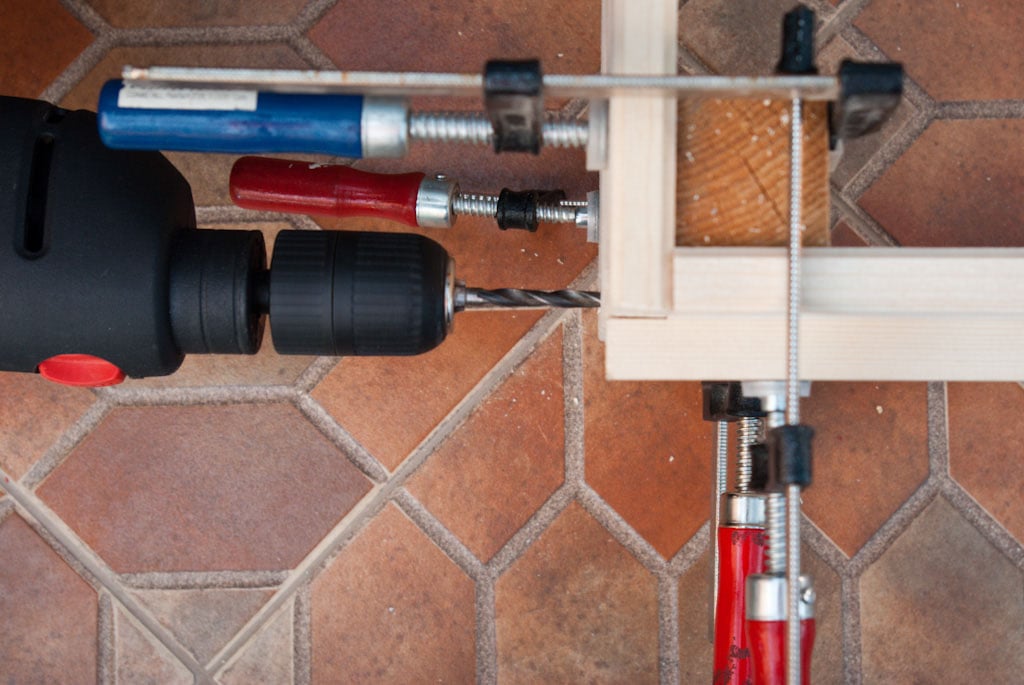

Clamping the bed frame corner joint to drill

In this image you can see the process from another angle. You can notice that the drill machinery is perfectly aligned with the wooden boards. The drill machine must be hold with one hand like a gun, with the index finger on the start button.

Hold the drill’s handle firmly with the other hand, in order to have greater control. The drilling must be progressive: at first use low speeds to create a shallow hole. Afterwards, the speed should be increased, but at every few seconds pull the drill slightly out and press it back in again, as not to block it in wood.

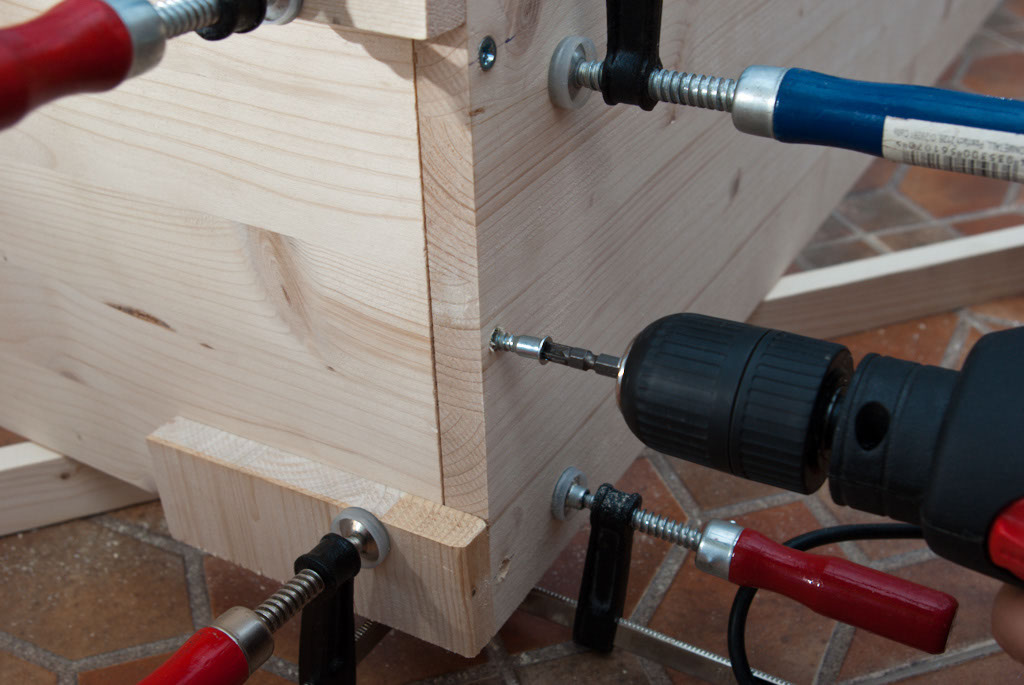

Tightening the bed frame joints with wood screws

After we have drilled the holes, we drove in the wood screws, using an electric screwdriver. Set the tool at low or average speed, to prevent the wood from splitting. In addition, do not insert the screw too much in the hole, because it might damage the wood board.

Wood bed frame

If you notice that the corners are not right angled, then you made a mistake during the process. Measure the diagonals of the frame and make adjustments, until they are equal. That is why, we strongly recommend you to use the framing square every time you make a corner joint. In this way, you could avoid a critical error, which would compromise the project.

Throughout the whole project, the bed frame should stand above the floor’s surface, ideally on several 2×2 slats. In this way, you would avoid damaging the floor and can secure the frame better.

Bed frame corner joint

The corner joints should be perfectly square, as you can see in the image. Make sure there is no space between the two boards, because even a small gap can damage the bed frame, on the long run. Use a pocket hole system, if you want to hide the joints.

Wooden bed frame side railings

The bed frame must also have side railings, before installing the slats. We have used 2×2 lumber and have fastened it with screws, every 1′ / 30 cm. Use a spirit level before inserting the screws, as to make sure the side railings are level.

You can also notice in the image that the side railings are supported by two 2×2 lumber pieces, as to leave a space from the bottom of the bed frame boards. The height at which you install the side railings will determine the height of the mattress, after you fit it inside the bed frame.

Installing the slats on a wooden bed frame

Next, we’ve painted the bed frame with a dark brown wood paint, as to give it a classical looks.

Afterwards, we have installed the slats, as you can see in the image. The slats don’t have to be screwed in, but you must make sure they are placed over the side railings, at equal distances one from another (10-15 inches will do just fine). In our project, we have reused the slats from an old bed frame, after we have polished and covered them with protective paint, against wood decay.

Installing plywood over bed frame’s slats

The last step is optional, and it’s up to you if you want to install an additional plywood sheet over the slats. We have decided to add this extra-layer in order to better distribute the weight on the whole surface of the bed slats. Buy a piece of plywood, making sure the material is 1/3” thick.

Consequently, the pressure exercised in the middle of the bed decreases, leading to a longer lifespan of the bed frame. In addition, the comfort will improve, as the surface should be perfectly horizontal. You can choose an average quality plywood, which should at least 1/3” thick.

How to build a bed frame

If you want to install legs to your bed frame, then you have to cut a 4×4 post, to the exact dimensions you want. Usually, we recommend a clearance space of at least 2”, between the bed frame and the floor. Consequently, the wooden legs must be cut at more than 6-7”, as they must be secured to wooden boards, using screws.

Fill the head of the screws with wood putty. Sand the surface, before applying several coats of stain.

Thank you for reading our article on how to make a wooden bed frame and we recommend you to check out the rest of our projects. Don’t forget to LIKE and SHARE our projects with your friends, by using the social media widgets. SUBSCRIBE to be the first that gets our latest projects.

2 comments

nice work, I needed it. it have help me

You’re welcome. Looking forward to seeing how your bed comes out!