Hello everyone, I am Bren! My last project which was a video game console worked out very well, so I thought it was time to step up my game. My wife had been expressing some interest in a new coffee table for our living room for her birthday so I figured the best way to ensure a quality coffee table was to make it myself. My better half liked a plan in the book I got for Christmas, “I can do that, woodworking projects”. There was a nice contemporary coffee table that didn’t call for any expert level construction but was definitely going to be a challenge since it would be the focal point of our living room.

The first step was to determine which type of wood it would be constructed from. Pine was out of the question, even though it was inexpensive ands easy to work with it would not hold up to wear and tear. Also from my experience (limited as it may be) it was difficult to get a really nice professional looking finish on pine if it was going to face the day to day scrutiny of coffee table status. The next logical choice was oak, which runs about 2X the cost of high quality pine here or 4 X the cost of knotty pine. I also checked out other available wood species like cherry, maple, walnut and mahogany but in the end the cost and availability of oak meant I could get a good pick of the lumber I needed. I could just stain it if I wanted it to resemble any of the rarer species. Just so I am clear on the high price of wood here and disparity, a 1 X 6 X 4 piece of oak is $17 before tax while a piece of prime pine is about the same cost for 1 X 6 X 8.

I would need 8, 1 X 6 X 4 pieces of oak for the table top and bottom shelf, along with 1 X4 for the legs and 1 X 3 for the skirts. I head to my local home improvement store in search of the building materials, and managed to find 5 good 1 X 6 X 4 pieces at one and then had to head to the other end of town to find the other three pieces. Since they were almost $20 a piece I didn’t want to settle for any pieces that wouldn’t look good in the middle of my living room. I was actually shocked that anyone would buy most of the wood that was available, it was full of knots, marks and splintered edges. Nonetheless after some searching I had a good starting material base for my table. See all my Premium Plans in the Shop.

Building a coffee table

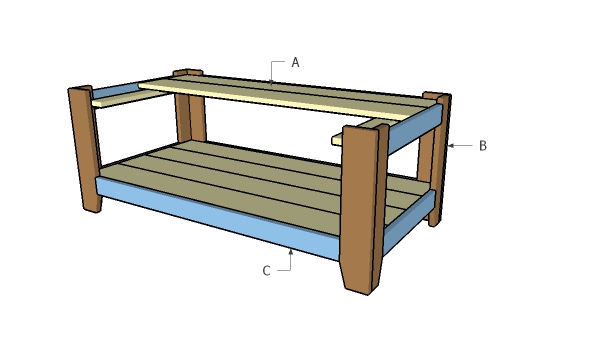

See the full plans with a complete cut list and lots of diagrams HERE. The plans are free and come with lots of useful information so you can build a table like the one Bren made.

How to build a contemporary coffee table

The first step once I got all the wood home was to sand it down, I figured I would sand it while it was full pieces rather than assembled. It took about 2 hours but I sanded each piece with 120 grit on the random orbit sander and then 220 with the detail sander. I altered the plan slightly which called for 40 ½ inch table top and bottom shelf. Since our living room is fairly large and I had the 48” boards I went with 44.5” table top and shelves. I figure I would leave few inches to trim the edges and remove the end part that had the price stickers attached. I really wish they would put those stickers on the end of the boards instead of a few inches up on the face, or at least put them at the very end of the boards.

Next step was to cut the 44.5” pieces, I measured as accurately as possible and started cutting. Obviously for things like a table top you need the pieces to be as close to exactly the same size as possible. Once I had the pieces cut I used the random orbit sander to make them as close to exactly the same size as possible. This took a bit of time but in the end I had 8 just about exactly the same size boards.

The plan called for attaching the boards using battens across the bottom ¼” shorter than the boards across. I was considering using pocket screws to attach the bottom pieces to each other and had seen that in other plans, but after some research it seemed like you needed some room for expansion and contraction of the wood which the pocket screws would not provide for. The plan also did not call for gluing the boards, my experience tells me gluing provides extra strength but also makes for a bad finish if all the extra glue is not cleaned up and sanded away. I did not want any ugly spots on my table top so I was happy enough to skip any gluing of the boards. Again, gluing would not allow for any movement of the wood once it was attached.

I cut the three battens at 21 ¾”, and attached one 2” from each end and one to the middle of the table top and shelf, each batten had 4 pre-drilled counter sink holes lined up with the middle of each table top and shelf board. I used clamps to keep the boards in place and attached the battens using 1 ¼” wood screws. You DO NOT want to drill the screws in too far or they will puncture the table top. Once this process is completed for the top and shelf make sure everything is equal width and length, there is still time to turn back by simply unscrewing the battens if there are any problems. If the boards were carefully measured and clamped while attaching the battens there should be no issues.

Once the top and shelf were complete it was time to cut the wood for the legs. Each leg in the plan was 18” high but I decided to make mine 17 3/4” so I could make the four legs from 2, 6’ pieces of oak. In order to give the legs a square look, the plan called for ripping ¾” from one half of the 1 X 4 for the legs. For simplicity sake I decided to use 1 X 3 for the back side of the legs, I’d only be giving up ¼” but saving a lot of potential for uneven leg cuts. As it turns out I was right, you can’t notice the ¼” as long as you keep the leg positioning consistent.

The plan called for the legs to extend ¾” above the table top and had 15-degree angle cuts at the bottom which ended about 4” up each leg. I had to put my math skills to work in figuring out where the start the 15 degree cut. If you divide 45 degrees by the given degree level you can figure out the ratio. So in this case 45/15 = 3, so I would have to start my cut about 4/3 = 1.3 inches in from the end of the board. I put a stop in place on my mitre saw to ensure the board would be in the correct position and made the cuts as even as possible.

It was a bit awkward since the boards were perpendicular to the mitre saw but I just braced them against my body while making the cuts. It might not have been textbook but it worked well. The stop had to be repositioned for the 3” board portion of the legs. Once all the leg pieces are cut, check to make sure all lengths are the same, if not trim and sand to make them as close to the same length as possible. All this takes a bit of time of course but is well worth the effort in the end. Once all the leg pieces are properly cut, apply glue to the long edge of the 3” boards, clamp them to a 4” piece and the legs are complete once the glue dries. Make sure you orient the legs so the 3” pieces all face the ends of the top and shelf boards, I will show it in the pictures.

Once the top, shelf and legs are completed it’s time to start construction. In order to ensure a ¾” gap between the leg and table top you need to put the table top upside down on a couple of pieces of ¾” scrap wood. As it turns out, two soda cans on top of each other provide the perfect gap between the top and bottom shelf. So you just put two cans at each corner of the upside down top and place the shelf upside down on top of those. Then you orient the four legs into place and pray that everything fits nicely.

Again if you are careful with all the cuts it will fit. If anything is out of line you need to make adjustments at this point, don’t try to make it fit if it doesn’t. Once everything is lined up you need to drill two screw holes on each side of the legs to join them to both the top and bottom shelves. I used a #8 counter sink drill bit to make the holes about 1” in from the edge of each side of the legs. You want to make sure the screws go into the very middle of the top and shelf to avoid any protruding out through. I used the 1 ¼” wood screws to attached the bottom shelf first (which was actually on top since the whole operation was upside down). I could then slide the ¾” scrap from beneath the top, take out the cans used to support the bottom shelf, then place the top back into place with the ¾” scrap underneath. Once everything in lined back up attach the top with screws and all that’s left are the side and end skirts.

The side and end skirts which were made from 1 X 3 need to be snug to each leg, any gaps would make it look shabby and after all this work the finishing touches make all the difference. I carefully measured all the side and end distances, marked the boards and cut just beyond my markings. I figured it was better to sand down or trim the skirts with the mitre saw then to cut too short and have to throw it away. Most were cut very close to fitting, there was just a little go over with the orbital sander to make things fit snugly. One or two needed a little trim with the mitre saw but that was no big deal. Each skirt was attached to the legs using a pocket screw on the bottom edge of the skirt and a few finishing nails on the top of the skirt to attach it to the shelf. I drilled pilot holes for each 3d finishing nail and sunk each nail with a nail set. I only used three nails for each side skirt and two nails for each end skirt. Once the skirts are fit and attached, the construction portion is complete, then it’s on to finishing the table.

I had pre-sanded each piece but went over everything with the 220 grit detail sander again. I also used wood filler for all the counter sink screws and nail heads. Next up was to decide on the stain and it took me a lot of internal debate to decide on oil vs water based stain. The benefit of water based is quick drying, low odor, easy clean up and wider array of color options. The oil based simply goes on better and sinks in deeper. Since I had lots of time, had a ventilated garage, was using disposable foam brushes and wanted the most even finish possible I went with the oil based stain.

My much better half decided on English Chestnut as our color of choice. The stain went on very easily using the 3” foam brush which helps control drips and runs over the edge of the wood, I really think foam brushes are the way to go with oil based stain. The stain needs to sit for 5 to 15 minutes so my plan of attack was to stain the top, skirts, bottom shelf, flip over, stain bottom of bottom shelf, stain bottom of top. After each section I would wait ten minutes then wipe off access with disposable shop towels folded into fourths, you also need lots of disposable rubber gloves for this type of project. This worked very well since it only took me about five minutes to stain each section and with the oil stain, and if you get a drip onto another section you just need to rub it in but I didn’t have much of that.

After about two hours I had coat number one complete and let it dry for a full day. The table looked really good after one coat but I thought I would do a second coat to add a depth to the finish. In the end it was a good choice because the second coat gave it deeper color, you could get away with one coat but the second coat definitely made it better.

Once the staining was complete I had to decide on the finish coat. Again I had to decide between water based poly vs oil based. After doing my research again it came down to the water based drying quicker, low odor and being easier to clean up. Since I had invested a full week of effort into this project I didn’t want to cut any corners and with the foam brushed didn’t care about clean up.

I cracked open the garage door, set up a fan and went to work on the finish coat. The oil based polyurethane was easy to apply and smooth out, made very little drips and since it didn’t dry as fast as the water based there was extra time to correct any issues. I applied the first coat in the same cycle as the stain and waited a day for the first coat to dry. Once the first coat was dry it was looking good but didn’t have the depth of finish I wanted. I lightly sanded the surface with 220 grit sandpaper which evens the surface and allows for better adhesion with the second coat. I then applied the second coat and waited a day for it to dry. After the second coat of poly the finish was looking really good, I decided a third coat wouldn’t be required.

Since this project was a birthday gift I wanted it to be the best it could be. There were a couple of minor issues along the way but overall I was pleased with the finished product.

Thank you for reading our project about how to make a wood coffee table and we recommend you to check out the rest of the projects. Thank you Bren for this great project! You instructions are amazing, as well! Don’t forget to LIKE and SHARE our projects with your friends, by using the social media widgets. SUBSCRIBE to be the first that gets our latest projects.

3 comments

Another amazing project, Bren. It seems that building this table was quite an adventure, but you pull it through nicely.

I just wanted to say that I really appreciate your attention to detail in every project I have seen here. I am going to tackle the bunk bed plans, and after that I want to do the coffee table. I will follow your projects and keep you posted on mine as well!

Thank you for sharing!

Thank you for the nice words and looking forward to seeing your projects.