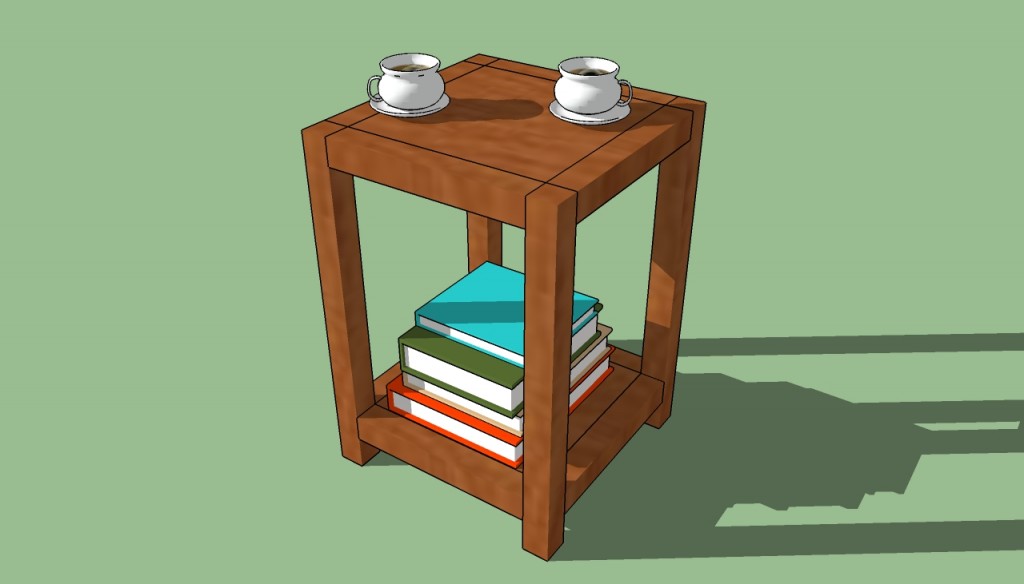

This step by step diy article is about how to build an end table. Building a simple end table from wood is a great way to add character to any room, as it will freshen-up the look of blunt corner. Use 2×2 lumber to build the frame of the table and several pieces of MDF or hardwood veneer plywood to make the top and the bottom shelf. Drill pocket holes, drive in 1 1/4” wood screws and apply a good glue to join the components together properly.

Adjust the end table building plans to your needs, while using the same woodworking techniques to get the job done by yourself. Measure the components several times before making the cuts, otherwise they might nor fit together smoothly. Use a pocket hole jig to drill the pilot holes, in order to prevent the wood from splitting. Work with good judgement, if you want to build your own table like a pro.

In order to get the job done in a professional manner, we recommend you to glue the MDF or the hardwood veneer plywood to the lumber, instead of using screws. If you drive in screws you would damage the material and not obtain a rigid joint. On the other hand, by applying a good glue to the edges of the components and locking them tightly with several clamps, you will both obtain a neat look and rigid joints. See all my Premium Plans in the Shop.

Made from this plan

In order to build a wood end table, you needs the following:

Materials

- 4 pieces of 2×2 lumber – 20″ LEGS

- 8 pieces of 2×2 lumber – 11″ APRONS

- 2 pieces of 3/4” MDF or hardwood plywood – 11″x11″ TABLETOP

- 1 1/4” wood screws – SCREWS

- Wood glue

- 1 piece of 3/4″ plywood – 2’x2′

- 2 pieces of 2×2 lumber – 8 ft

- 2 1/2″ screws

- 1 1/4″ screws

- glue, stain

- wood filler

Tools

- Safety gloves, glasses

- Miter saw saw, jigsaw

- Chalk line, tape measure, spirit level, carpentry pencil

- Drill machinery and drill bits

- Pocket hole jig

Tips

- Pre-drill holes in the wooden components, before driving in the screws

- Smooth the exterior edges of the components, by using a router with a 1/4” bit

Time

- One weekend

Build your own end table

Building a small end table by yourself is not as complicated as it might seem at first glance, if you use the right plans for your needs and appropriate woodworking techniques. Design the table as to fit your tastes, before writing down the materials required for the project.

How to build an end table from wood

Building the top of the table

Firstly, build the top of the end table, as well as the bottom shelf. Therefore, you need to use two pieces of 2×2 lumber and a piece of MDF or hardwood veneer plywood. In order to glue the components together, just apply a lot of glue to their edges and clamp them tightly.

Attaching the side aprons

Next, start building the frame of the end table, while letting the glue to dry out properly. Therefore, cut the 2×2 lumber a the right size to build the legs and the side aprons of the table.

Lay the pieces of lumber on a level surface, making sure they are perfectly aligned one with another. Check the corners for squareness, before drilling the pocket holes and inserting the 1 1/4” screws.

Attaching the tabletop

After you have built both sides of the table, as well as the table top, you should lock them together. The process is straight-forward if you use the right woodworking techniques. Turn the frame upside-down and fit the table top, making sure the components are aligned properly.

Building the bottom shelf

The next step is to attach the bottom shelf to the table, in the same manner described above. Work with great care and judgement, if you want to obtain a professional result. Make sure the shelf is perfectly level, before driving in the 1 1/4” wood screws. If you have followed our instructions and have use the right tools for the job, the end table should look similar to the one in the image.

How to build an end table

Last but not least, before using the wooden-made end table, you need to take care of the finishing touches. Therefore, you need to fill the holes with a good wood putty and let the compound dry out properly for several hours. Afterwards, sand the surface with medium-grit sandpaper and clean the dust with a dry cloth.

Thank you for reading our article about how to build an end table and we recommend you to check out the rest of our projects. Don’t forget to share our articles with your friends, by using the social media widgets.

EXPLORE MORE IDEAS:

1 comment

Nice table.

Just a question on attaching the table top, are the pocket holes to do so on the table top its self or in the 2×2’s?

Thanks